Technical Specifications (Technical Agreement)

Basic functions

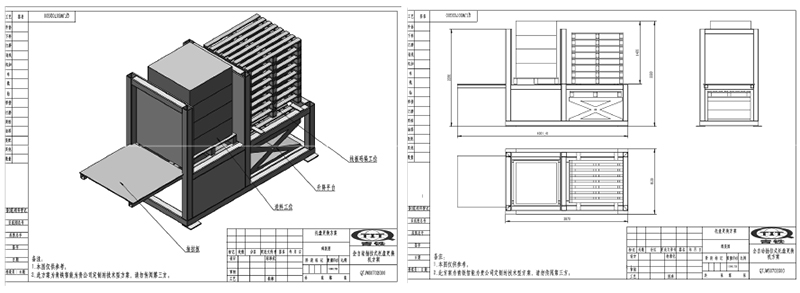

This machine is used to replace goods placed on plastic pallets with wooden pallets or other types of pallets (hereinafter referred to as shipping pallets).

Basic characteristics

(1) Each moving component is equipped with a dual protection switch device (limit switch, mechanical limit device) to ensure safer operation of the entire machine.

(2) Adopting an independent wireless control handle and sound and light warning lights, it has good operability and safety.

(3) The integrated design of the pallet changing mechanism and pallet stacking mechanism is efficient and easy to use.

(4) Open upper space with no restrictions on product height/number of floors.

(5) The device has high integration and can be moved according to actual usage conditions.

(6) The overall design can adopt electric and integrated hydraulic power systems to overcome the problem of insufficient air supply.

Main performance indicators

Item No. | content | Indicator requirements | Definition and conditions of performance guarantee values |

1 | A homework process time | 28 seconds ± 10% | Excluding manual placement of shipping pallets and delays in manual control operations |

2 | Maximum load-bearing capacity for changing pallets | 1.8T | Equipment structural load-bearing strength |

3 | Comprehensive reliability of equipment | ≥99.9% | After passing the acceptance inspection, the equipment will be put into production. Within three months, it will be operated in units of 8 hours per shift, with a reliability of 98% and no faults (under normal use of the equipment) |

4 | Number of malfunctions during the assessment period | ≤ 1 | During the assessment period (when the equipment is in normal use), the machine's own failure rate is less than 3% (in units of 8 hours per shift) |

5 | Equipment noise | ≤ 80 decibels |

Product size

Length x Width: 1000x1200x160mm

Cargo height: 400mm -1700mm (including pallets, theoretically unlimited overall height)

Weight: MAX 1.8 T (The maximum static load capacity of the equipment, including the goods, is 1.8 tons. Party B does not guarantee the loss of outer box wear and tear caused by the weight of the goods (products) due to the pushing or pulling of the pallet and goods).

Tray weight: ≤ 30kg

Tray surface requirements: Plastic tray (smooth surface, no anti slip device for pulling direction).

Homework process (can optimize the process during production)

serial number | job description |

1 | Initial state: The elevator is located at the feeding station, and the pull plate is located at the tray collection position |

2 | Start up, extend the plug and pull board outward, and wait for the goods on the lifting platform |

3 | The forklift places the goods onto the lifting platform, and the clamping plate clamps and fixes the goods |

4 | Start the sliding board and the plastic tray on the lifting platform to move to the right simultaneously, and transfer the goods to the sliding board |

5 | The insertion and pulling board arrives at the purchasing station, and the goods are completely transferred to the insertion and pulling board. The lifting platform lifts the plastic pallets to the stacking mechanism for collection and stacking of plastic pallets |

6 | Forklift with wooden pallet enters the feeding station to wait for goods, and the clamping plate is released |

7 | Start the pull plate to pull out to the outside, transfer the goods to the wooden pallet of the forklift, and the forklift will track the goods out. At the same time, the lifting platform will move to the left of the feeding station to reset and wait for the goods |

8 | The forklift places the goods onto the lifting platform, and the clamping plate clamps and fixes the goods. At this point, the insertion and extraction plate extends outside the machine |

9 | Start the sliding plate to move to the left towards the feeding station, transfer the goods to the sliding plate, and at the same time, the lifting platform with plastic pallets moves to the right towards the pallet collection position |

10 | The goods are completely transferred to the pull-out board, and after the lifting platform is in place, the plastic pallets are lifted to the stacking mechanism for collection and stacking |

11 | Forklift with wooden pallet enters the feeding station, and the clamping plate is released |

12 | Pull out the plug and pull board towards the side of the machine, transfer the goods to the wooden pallet, and reset the lifting platform to the feeding station for waiting for the goods |

13 | The forklift places the goods onto the lifting platform of the feeding station, and at this time, the insertion and pulling plate extends outside the machine |

14 | Repeated homework |

15 | Stop the task and restore the machine to its initial state |

Shanghai Baoduan Machinery Manufacturing Co., Ltd. is located in Baoshan District, Shanghai, an international metropolis. It is a professional mechanical production enterprise engaged in equipment manufacturing and equipment R&D.

The company focuses on production equipment for metallurgical processing, as well as winding and packaging machine equipment for metal strips, pipes, profiles, tires, etc. Meanwhile, to solve problems such as product packaging and transfer in the actual production of metal strip processing enterprises, our company has also developed winding and packaging equipment for materials like metal strips, metal plates, pipes, and wires—including steel strip Winding Machines, copper coil winding and packaging machines, steel wire winding machines, steel pipe winding machines, horizontal winding machines, etc.—as well as industrial turning equipment such as 90-degree Steel Coil tilters, aluminum Coil tilters, Mold tilters, and 180-degree tilters.

Shanghai Baoduan Machinery Manu-facturing Co., LTD is located inBaoshan DistrictShanghai. Is a professional equipment manufacturing.

About

Copynght @ Shanghai Baoduan Machinery Manufacturing Co, LTD. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.