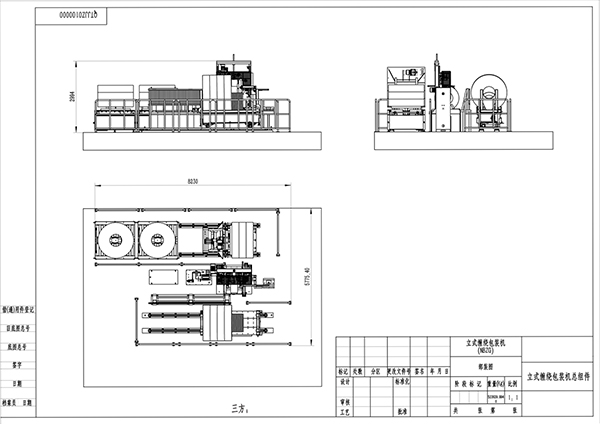

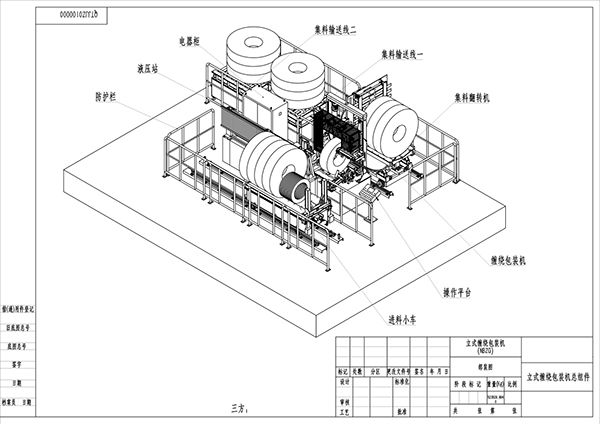

The Vertical Packaging Machine is a multi-functional and automated packaging equipment, which is widely used in industries such as food, pharmaceuticals, and chemical engineering.

Working Principle

Material Feeding: Packaging materials are conveyed to the hopper of the packaging machine via an automatic feeding device, ensuring a continuous and stable supply of materials.

Bag Formation: Roll film material is used, and the roll film is formed into a bag shape by a forming device. The forming device ensures that the size and shape of the bag meet the preset standards.

Filling: After the bag is formed, materials enter the interior of the bag through a filling device. The filling device can

adopt different filling methods (such as screw filling, bucket elevator, etc.) according to the characteristics of the materials.

Sealing: After filling is completed, the top of the packaging bag is automatically sealed. The sealing device usually adopts heat sealing or cold sealing technology to ensure a firm and reliable seal and prevent material leakage.

Cutting: After sealing is finished, the packaging bags are cut into individual ones by a cutting device. The cutting device usually uses blade cutting or heat cutting methods to ensure neat cuts.

Discharging: The finished packaging bags are discharged through a conveyor belt or other conveying devices and enter the next process, such as cartoning, palletizing, etc.

Equipment Characteristics

Efficient Operation: It adopts an advanced automatic control system, and the entire packaging process is completed in one go. This greatly shortens the packaging cycle, improves production efficiency and capacity, and reduces labor costs.

Accurate Measurement: Equipped with a high-precision metering device, it can achieve precise control for solid particles, powders, or liquids, ensuring that the product content in each packaging unit is accurate.

Flexibility and Versatility: By replacing different molds and accessories, it can quickly switch between packages of different shapes and sizes. At the same time, it supports the compatible use of various packaging materials, expanding the scope of packaging applications.

Intelligent Control: It integrates advanced intelligent control technologies, such as PLC (Programmable Logic Controller) and touch-screen human-machine interface. Operators can realize the automatic operation and monitoring of the equipment only through simple parameter settings.

Environmental Protection and Energy Saving: Through optimized structural design and the adoption of energy-saving materials and technical means, it reduces energy consumption and noise pollution during the operation of the equipment. Meanwhile, it supports the recycling and environmental protection treatment of packaging waste.

Application Fields

Food Industry: It can be used for packaging rice, flour, candies, potato chips, coffee powder, milk powder, etc.

Pharmaceutical Industry: It can be used for packaging medicinal powders, tablets, etc.

Chemical Industry: It can be used for packaging fertilizers, plastic granules, washing powder, etc.

Daily Chemical Industry: It can be used for packaging cosmetics, detergents, etc.

Shanghai Baoduan Machinery Manufacturing Co., Ltd. is located in Baoshan District, Shanghai, an international metropolis. It is a professional mechanical production enterprise engaged in equipment manufacturing and equipment R&D.

The company focuses on production equipment for metallurgical processing, as well as winding and packaging machine equipment for metal strips, pipes, profiles, tires, etc. Meanwhile, to solve problems such as product packaging and transfer in the actual production of metal strip processing enterprises, our company has also developed winding and packaging equipment for materials like metal strips, metal plates, pipes, and wires—including steel strip Winding Machines, copper coil winding and packaging machines, steel wire winding machines, steel pipe winding machines, horizontal winding machines, etc.—as well as industrial turning equipment such as 90-degree Steel Coil tilters, aluminum Coil tilters, Mold tilters, and 180-degree tilters.

Shanghai Baoduan Machinery Manu-facturing Co., LTD is located inBaoshan DistrictShanghai. Is a professional equipment manufacturing.

About

Copynght @ Shanghai Baoduan Machinery Manufacturing Co, LTD. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.