When choosing a roll material flipping machine model, safety requirements are the core prerequisite for ensuring personnel, equipment, and roll materials, while automation requirements directly affect production efficiency, operational convenience, and process adaptability. Based on the risk points and automation goals of the production scenario, the following key requirements need to be evaluated in a targeted manner:

Core security requirement: Avoid personnel and equipment risks

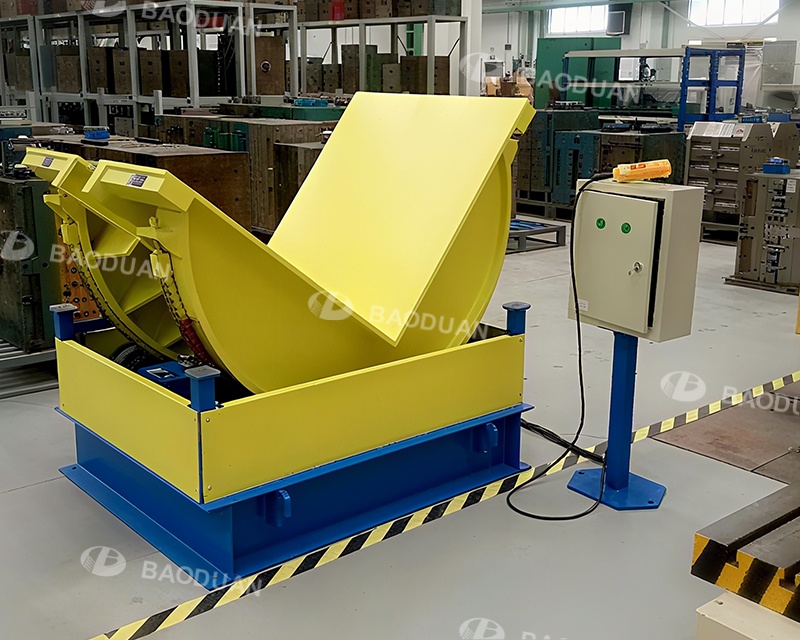

The operation of the roll material flipping machine involves key links such as "heavy object flipping", "mechanical movement", and "material fixation". The safety design needs to cover the entire chain of "preventing danger", "protection in case of danger", and "emergency stop control". The following dimensions need to be considered:

1. Mechanical structure safety: prevent material detachment and structural failure

Reliability of coil clamping/fixation: It is necessary to confirm whether the equipment has a clamping mechanism that is compatible with the type of coil, and whether the clamping force can be adjusted according to the diameter and weight of the coil - to avoid insufficient clamping force causing the coil to slip during flipping, or excessive clamping force causing damage to the coil.

For steel coils weighing over 10 tons, it is necessary to choose a model with "dual clamping detection".

Stability of flipping mechanism: Check the load-bearing level of core components such as flipping spindle, bearings, and transmission gears to avoid structural deformation or fracture during long-term operation; At the same time, pay attention to the flip angle limit device to prevent equipment from overturning or material from being thrown out due to over angle flipping.

Integrity of protective structure: The equipment needs to be equipped with physical protective barriers to cover the hazardous areas of flipping motion; If personnel frequently approach the production scene, it is recommended to choose a model with an "infrared photoelectric grating" - when personnel accidentally enter the protective area, the equipment will automatically pause and flip, triggering an audible and visual alarm.

2. Electrical and control system safety: avoid misoperation and loss of control

Emergency stop system: The equipment must be equipped with at least 2 independent emergency stop buttons at the operating position and around the equipment, and the buttons must be conspicuous, anti misoperation, and immediately cut off the power source when pressed, ensuring that the flipping action stops instantly.

Overload and fault protection: The control system needs to integrate an "overload detection" function. When the load exceeds the rated value of the equipment, it will automatically shut down and display a fault code; At the same time, it is necessary to have "phase failure protection", "leakage protection", and "hydraulic oil level/oil temperature protection" to avoid hardware damage and safety accidents.

Operation permissions and warnings: If the device requires collaboration among multiple personnel, it is necessary to support "permission grading" to prevent risks caused by accidentally modifying parameters; Before homework, there should be a "sound and light warning" to remind surrounding personnel to stay away from dangerous areas.

Key automation requirements: adaptation to production processes and efficiency goals

Automation requirements need to revolve around "reducing manual intervention", "improving job accuracy", and "achieving process linkage". Specific functions need to be selected based on the degree of automation in the production scenario

1. Operation automation: reduce manual intensity

One click flipping control: The ideal model should support a "preset program", where the operator only needs to select the type of coil, and the equipment automatically matches the clamping force, flipping speed, and flipping angle without manually adjusting multiple parameters, especially suitable for batch operations of the same type of coil.

Automatic alignment and centering: For scenarios that require precise docking with subsequent processes, models with "automatic alignment" function should be selected - using photoelectric sensors or laser rangefinders to detect the position of the coil, automatically adjust the position of the gripper or workbench, ensure that the center of the coil is aligned with the center of the subsequent equipment after flipping, and avoid manual calibration time.

Semi automatic auxiliary function: If manual assistance is still required for coil loading/unloading in production scenarios, models with "semi-automatic lifting" and "manual fine adjustment of clamping position" can be selected to balance automation and flexibility.

2. Accuracy and parameter controllability: ensuring material quality and process adaptation

Adjustable flipping speed and angle: Different materials of coils have different requirements for flipping speed, and the angle needs to match the requirements of subsequent processes. Therefore, the equipment needs to support "speed stepless adjustment" and "angle precise control", and be able to save multiple sets of parameters.

Real time parameter monitoring and recording: For scenarios that require traceability of production data, it is necessary to select a model with "data acquisition and storage" function - record the time, clamping force, flipping angle, and load data of each flip through the PLC control system, and export reports through touch screen or upper computer for quality traceability and equipment maintenance.

3. Linkage and integration capability: adapted to the automation system of the production line

Linkage with production line PLC/ERP system: If the equipment needs to be integrated into a fully automated production line, a model that supports "industrial communication interface" needs to be selected, which can be connected to the production line's main PLC or ERP system to achieve unmanned circulation of "automatically receiving production orders → automatically calling corresponding flipping programs → feedback signals to the next process after completion", without the need for manual instruction transmission.

Collaboration with auxiliary equipment: If it is necessary to use a feeding trolley, crane, or conveyor roller in production, it is necessary to confirm whether the flipping machine has a "signal interaction function" - for example, after the crane places the coil on the flipping machine workbench, it sends a "material in place" signal, and the flipping machine automatically starts clamping; After the flipping is completed, send a "material ready" signal, and the conveyor roller will automatically transport the coil to avoid waiting between processes.

Remote monitoring and maintenance: For scenarios where large factories or multiple workshops are distributed, it is recommended to choose intelligent models with "remote monitoring" function - by uploading the device's operating status to the cloud platform through the Internet of Things module, management personnel can remotely view operating data, receive fault warnings, and even remotely guide debugging, reducing on-site maintenance costs.

Summary: The principle of balancing safety and automation

When choosing, it is necessary to avoid "pursuing automation excessively and neglecting safety redundancy" or "focusing only on basic safety and reducing production efficiency". The core principles are as follows:

Safety priority: Regardless of the degree of automation, it is necessary to meet the three basic safety standards of "load-bearing safety factor ≥ 1.2", "emergency stop response time ≤ 0.5 seconds", and "no blind spots in the protected area". Especially for heavy and high-risk scenarios, additional dual safety guarantees need to be configured.

Automated adaptation production process: If it is a semi-automatic production line, priority should be given to selecting models with "one click operation+manual fine-tuning"; If it is a fully automated unmanned workshop, it must have the functions of "communication linkage+data traceability+remote monitoring" to avoid disconnection between equipment and the overall process.

Reserve expansion space: If there is a possibility of expanding production scale in the future, it is recommended to choose models with "upgradable clamping mechanisms" and "expandable communication interfaces" to avoid the need to replace equipment due to increased production capacity and reduce long-term costs.

Shanghai Baoduan Machinery Manu-facturing Co., LTD is located inBaoshan DistrictShanghai. Is a professional equipment manufacturing.

About

Copynght @ Shanghai Baoduan Machinery Manufacturing Co, LTD. All rights reserved

SitemapThis website uses cookies to ensure you get the best experience on our website.

Comment

(0)